3D-printed aluminum that withstands 572°F could reshape engine design

Source: interestingengineering

Author: @IntEngineering

Published: 12/16/2025

To read the full content, please visit the original article.

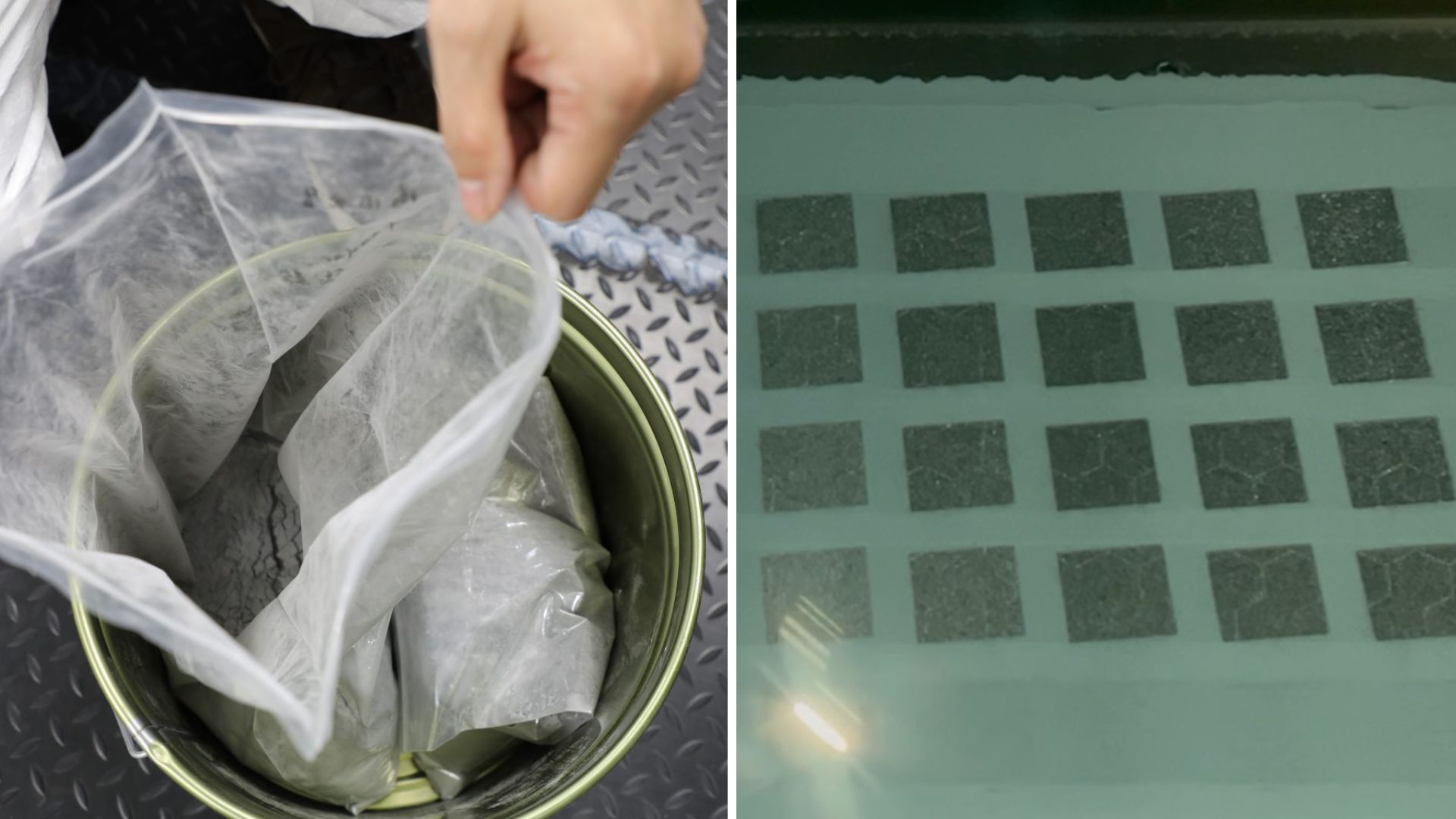

Read original articleResearchers at Nagoya University have developed a new class of 3D-printed aluminum alloys that defy traditional metallurgical rules by incorporating iron—previously considered a contaminant that weakens aluminum—alongside manganese and titanium. Using laser powder bed fusion 3D printing, which rapidly cools molten metal layers, the team created alloys with unique micro- and nano-structures that prevent the brittleness and corrosion typically caused by iron. This rapid solidification enables the formation of metastable phases that enhance both strength and heat resistance, allowing one alloy variant to maintain flexibility and strength at temperatures up to 300°C (572°F).

The breakthrough alloy (Al-Fe-Mn-Ti) not only achieves high strength at room temperature but also sustains exceptional mechanical properties at elevated temperatures, making it ideal for demanding automotive and aerospace applications such as engines and turbines. The materials are composed of low-cost, abundant elements and are designed to be recyclable, addressing sustainability concerns. Additionally, these alloys are easier

Tags

materials3D-printingaluminum-alloysheat-resistant-materialsautomotive-materialsaerospace-materialsmetal-alloys