3D-printed system recovers rare earth minerals from industrial waste

Source: interestingengineering

Author: @IntEngineering

Published: 2/7/2026

To read the full content, please visit the original article.

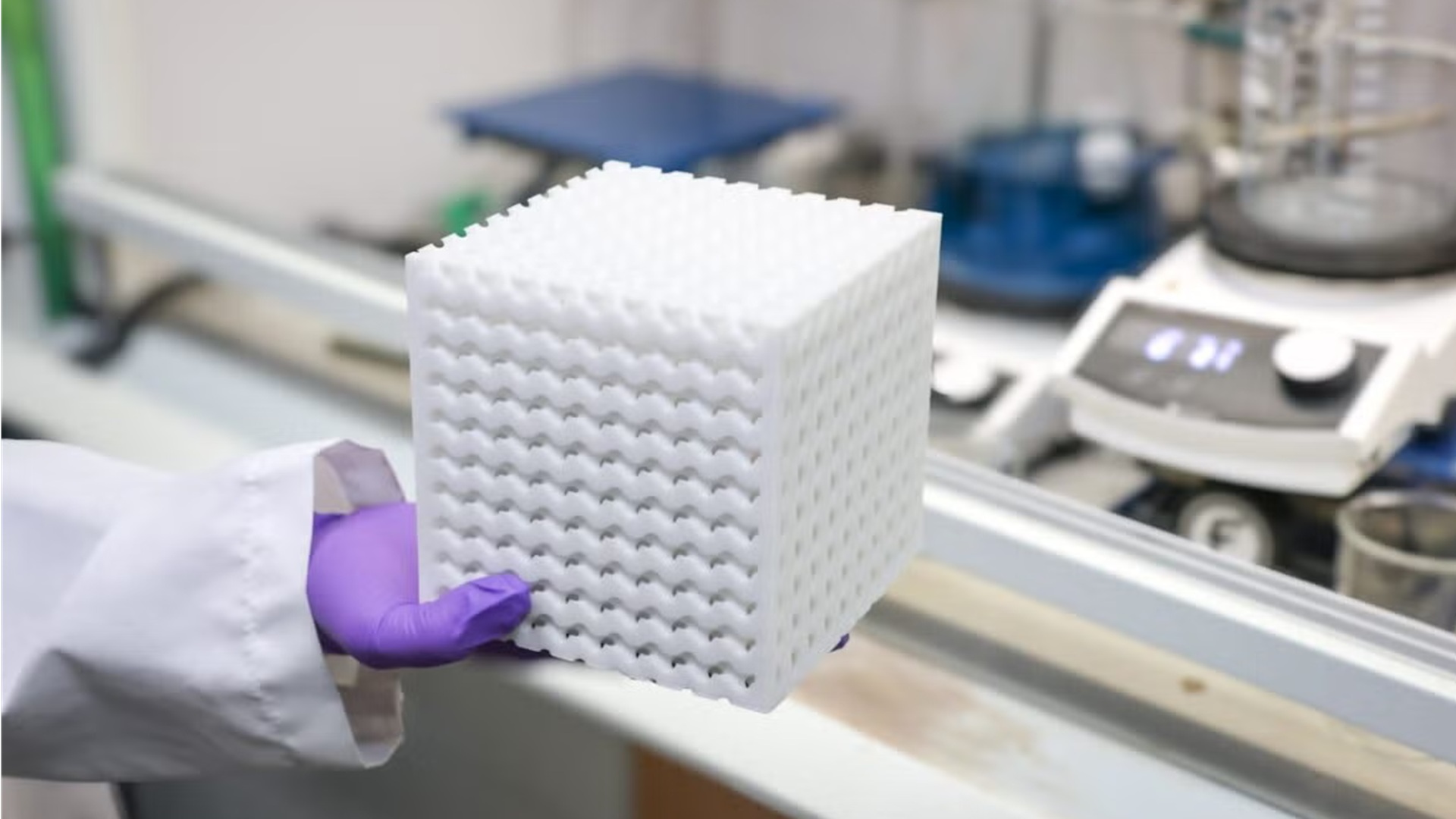

Read original articleSupra Elemental Recovery Inc., a U.S. startup spun out of The University of Texas at Austin, has developed a novel 3D-printed system to recover high-purity critical minerals such as lithium, cobalt, gallium, and scandium from domestic industrial waste streams, including mine tailings, electronic waste, and byproducts. Their proprietary technology employs a porous, cartridge-based design that functions like a molecular sponge, selectively capturing targeted elements through a combination of solvent extraction and ion exchange using simple solvents like alcohol and water. This modular, reusable system can be customized and scaled for various industrial applications, offering a cleaner, more cost-effective alternative to traditional mineral refining methods that rely on large machinery and harsh chemicals.

The startup aims to address the growing demand for critical minerals driven by the expansion of semiconductors, batteries, magnets, and defense systems, while reducing U.S. dependence on foreign supply chains that have proven vulnerable to disruptions and export controls. Supra’s approach not only promises economic benefits

Tags

materials3D-printingrare-earth-mineralsmineral-recoveryindustrial-waste-recyclingcritical-mineralssustainable-technology