3D printing breakthrough merges multiple materials in one print

Source: interestingengineering

Author: @IntEngineering

Published: 1/22/2026

To read the full content, please visit the original article.

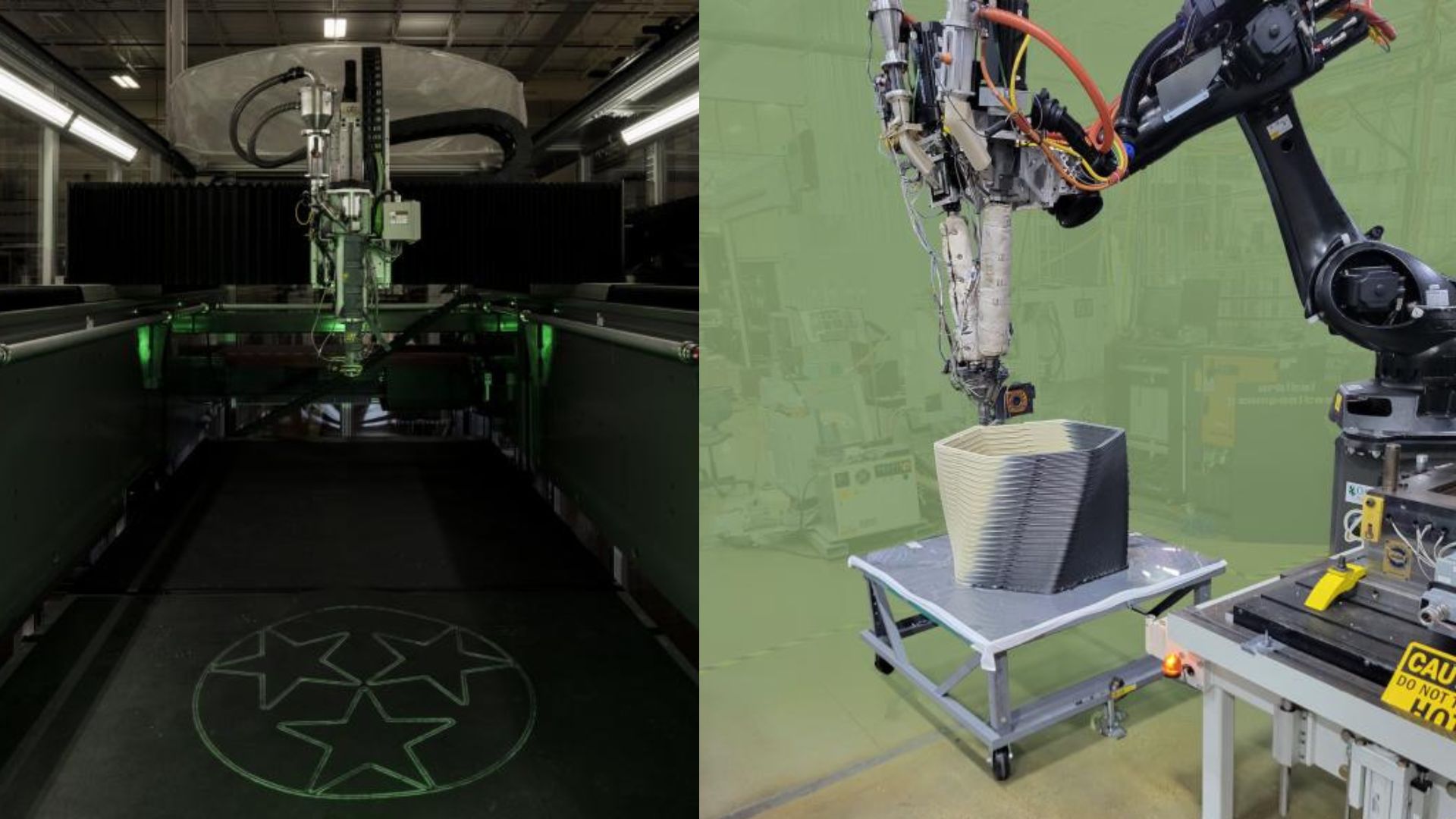

Read original articleResearchers at Oak Ridge National Laboratory (ORNL) have developed a novel extrusion system for large-scale 3D printing that merges multiple smaller extruders into a single high-output material stream using specially engineered nozzles. This innovation overcomes a key tradeoff in extrusion-based additive manufacturing: large extruders provide high volume but reduce precision and add weight, while smaller extruders offer control but lack scalability. ORNL’s modular system allows users to activate or deactivate extruders as needed, scaling output without sacrificing accuracy or increasing the mechanical burden on motion systems.

A standout feature of the technology is its ability to print multiple materials simultaneously within a single extrusion bead, eliminating the need for tool changes or separate print passes. This is achieved through patent-pending aluminum bronze nozzle blocks with Y-shaped internal channels that merge molten polymer streams, improving bead quality and doubling material flow. Additionally, a proprietary nozzle design enables core-and-sheath bead structures, combining different polymers to enhance mechanical properties and interlayer adhesion, addressing common

Tags

3D-printingadditive-manufacturingmulti-material-extrusionmaterials-engineeringpolymer-compositesmanufacturing-technologyOak-Ridge-National-Laboratory