Consumer 3D printers power super-resolution imaging optics under $1

Source: interestingengineering

Author: @IntEngineering

Published: 1/14/2026

To read the full content, please visit the original article.

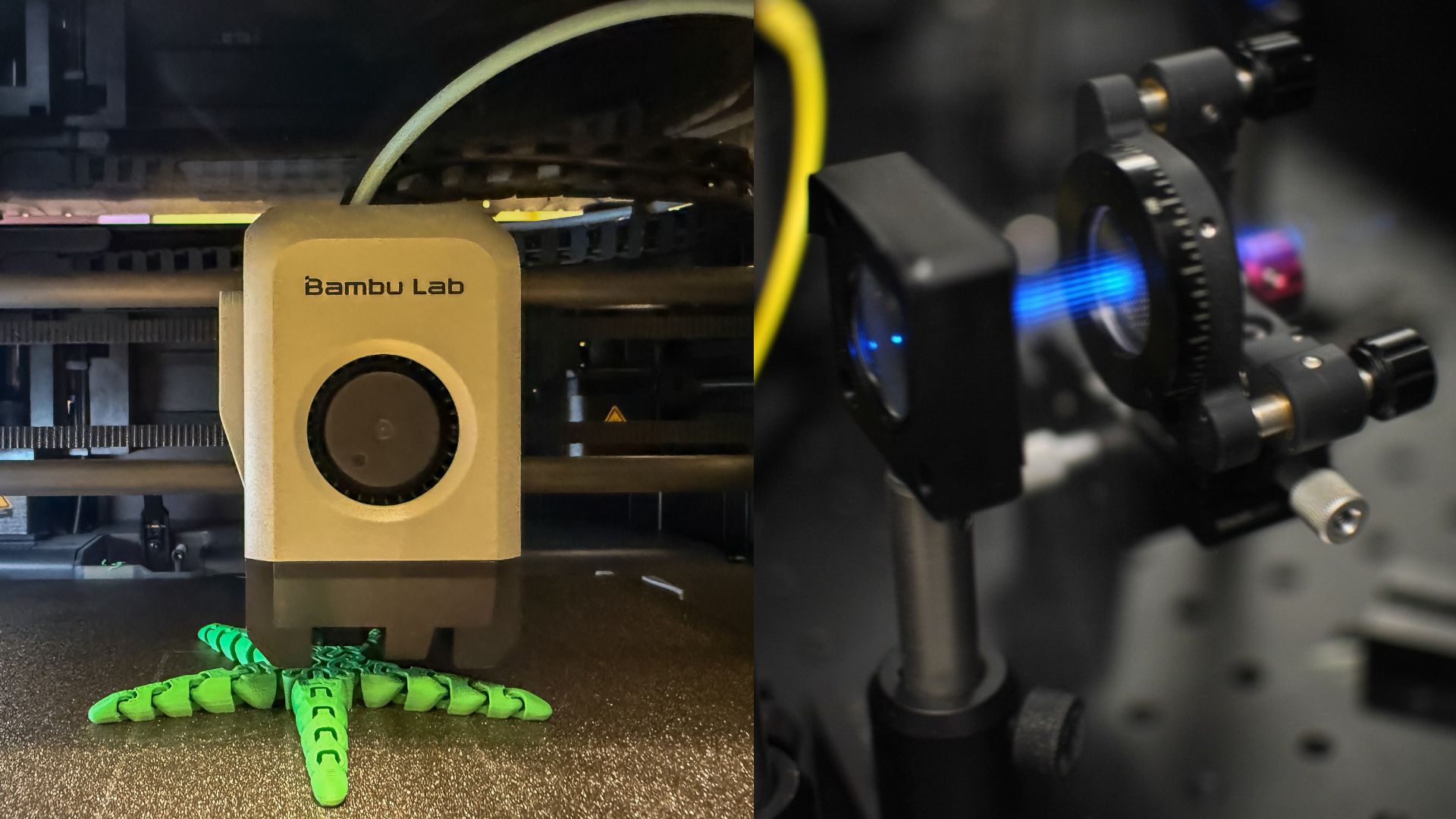

Read original articleResearchers from the University of Strathclyde have demonstrated that consumer-grade 3D printers combined with inexpensive materials can produce advanced optical components capable of super-resolution imaging at a cost of less than $1 per lens. By integrating 3D printing, silicone molding, and UV-curable resin, they fabricated multi-element lenslets that enable imaging beyond the traditional diffraction limit. These lenses were used to build a multifocal structured illumination microscope capable of resolving nanoscale biological structures, such as microtubules within a cell’s cytoskeleton, achieving a resolution of about 150 nanometers comparable to commercial super-resolution microscopes.

To overcome the optical scattering and diffraction issues inherent in standard 3D printing, the team developed a molding-based refinement process that smooths the lens surfaces without time-consuming polishing. They printed raw optical designs, added material to refine surfaces, then created silicone molds filled with UV-curable resin to produce high-quality lenslet arrays. These low-cost lenses matched the performance of both high

Tags

materials3D-printingoptical-componentssuper-resolution-imagingmicroscopysilicone-moldingUV-curable-resin