GE Aerospace uses robots to fix jet engine blades, reduce repair delay

Source: interestingengineering

Author: @IntEngineering

Published: 2/13/2026

To read the full content, please visit the original article.

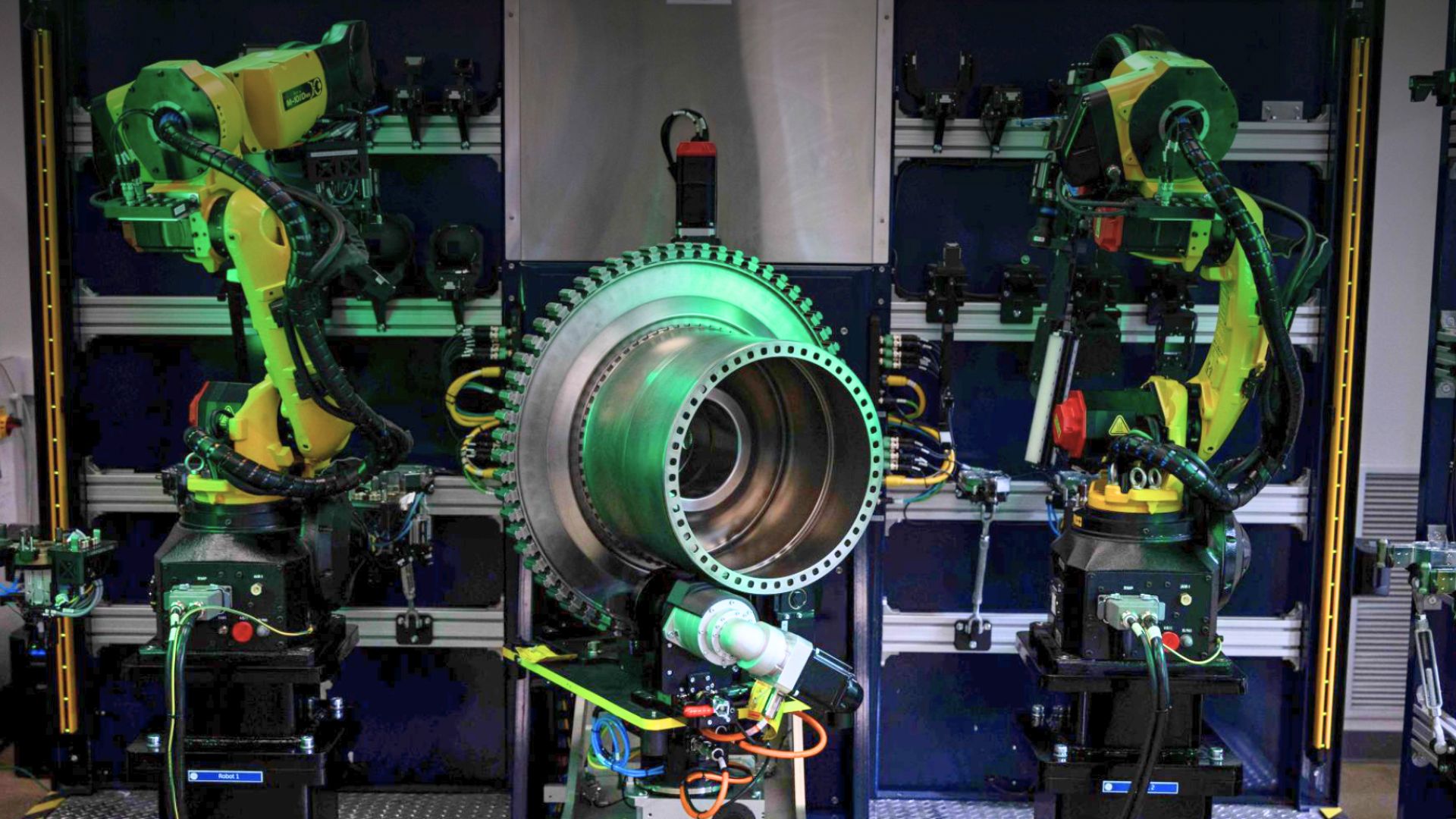

Read original articleGE Aerospace is advancing automation in its Singapore repair hub to address global delays in jet engine maintenance that have grounded aircraft for extended periods. The initiative focuses on translating the precise manual skills of veteran technicians, such as Suresh Sinnaiyan’s delicate compressor blade blending, into robotic processes. This shift aims to alleviate overloaded repair shops and spare parts shortages by increasing repair output by 33% without expanding physical space, supported by a planned $300 million investment in automation, digital tools, and AI.

The company is also reorganizing repair lines to improve turnaround times, notably reducing the repair cycle for CFM56 turbine nozzles from 40 days in 2021 to a target of 21 days by 2028. Preparing for maintenance on newer LEAP engines is a key priority, as faster repairs minimize aircraft downtime. By capturing skilled manual techniques in repeatable robotic systems, GE hopes to cut costs, reduce dependence on scarce skilled labor, and enhance problem detection. CEO Larry Culp emphasized a

Tags

robotsautomationaerospacejet-engine-repairmanufacturing-technologyroboticsindustrial-automation