Inexpensive diaphragm system powers 700-hour carbon conversion

Source: interestingengineering

Author: @IntEngineering

Published: 11/6/2025

To read the full content, please visit the original article.

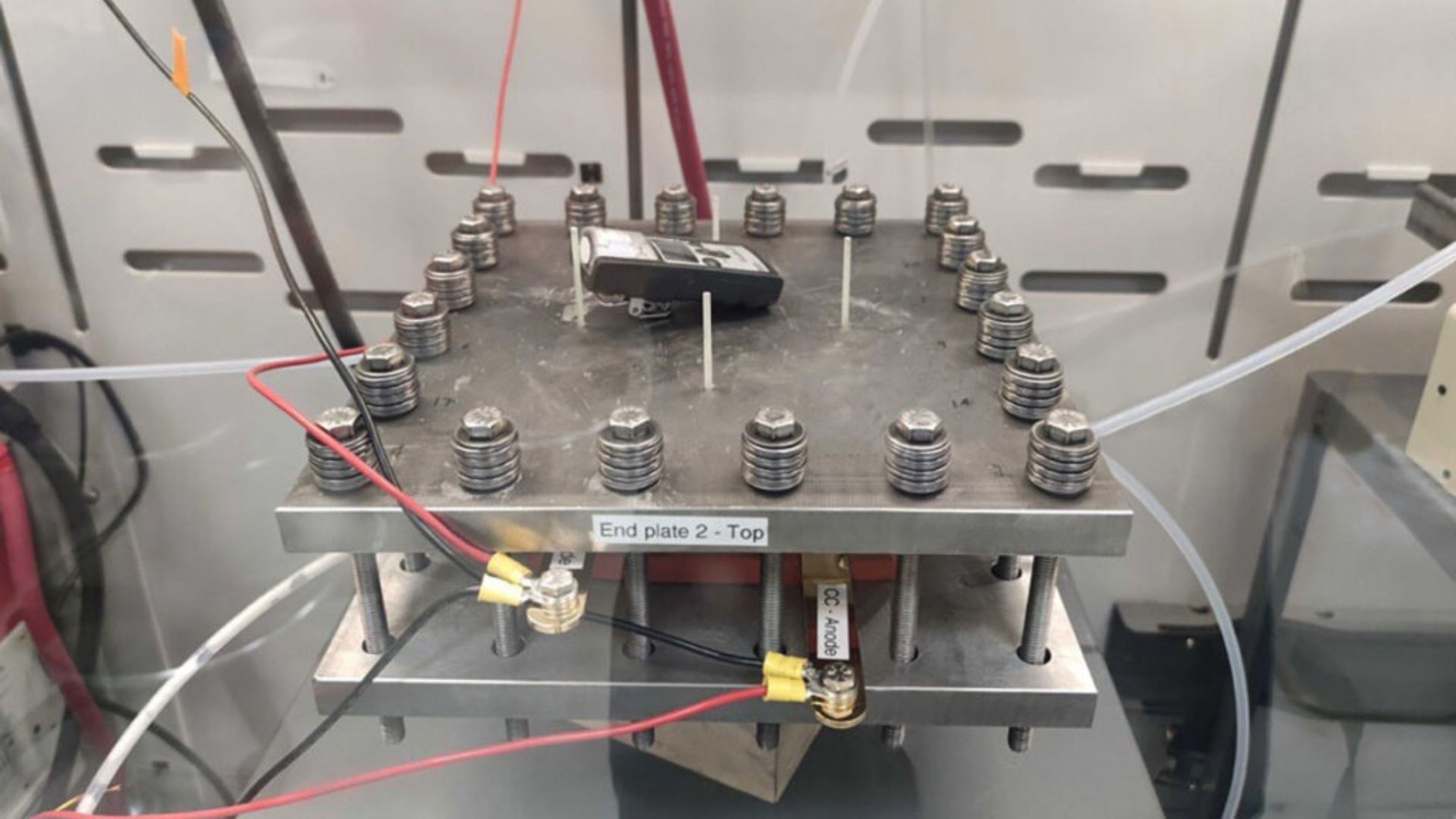

Read original articleResearchers at Washington University in St. Louis, led by Feng Jiao, have developed a durable and cost-effective diaphragm system that significantly improves the stability and efficiency of carbon dioxide conversion into carbon monoxide. This process is crucial for sustainable manufacturing, as carbon monoxide can be further transformed into fuels and chemicals using renewable electricity. Traditional systems rely on anion exchange membranes that degrade quickly when exposed to organic materials, limiting their practical use. The team demonstrated that porous diaphragms, such as the commercial Zirfon product containing zirconium dioxide, can replace these membranes without sacrificing performance, offering enhanced resistance to degradation and maintaining high efficiency over extended periods.

In tests, the Zirfon-based diaphragm electrolyzer operated efficiently for over 250 hours at 60°C, outperforming commercial membranes that typically last about 150 hours. A scaled-up version of the system ran continuously for 700 hours, showcasing its potential for industrial-scale applications. This advancement suggests that diaphragm-based designs could lower costs and improve the durability of carbon recycling devices

Tags

energymaterialscarbon-conversionelectrolyzerdiaphragm-systemsustainable-manufacturingcarbon-recycling