Laser-assisted 3D printing method forms ultra-hard tungsten carbide

Source: interestingengineering

Author: @IntEngineering

Published: 2/7/2026

To read the full content, please visit the original article.

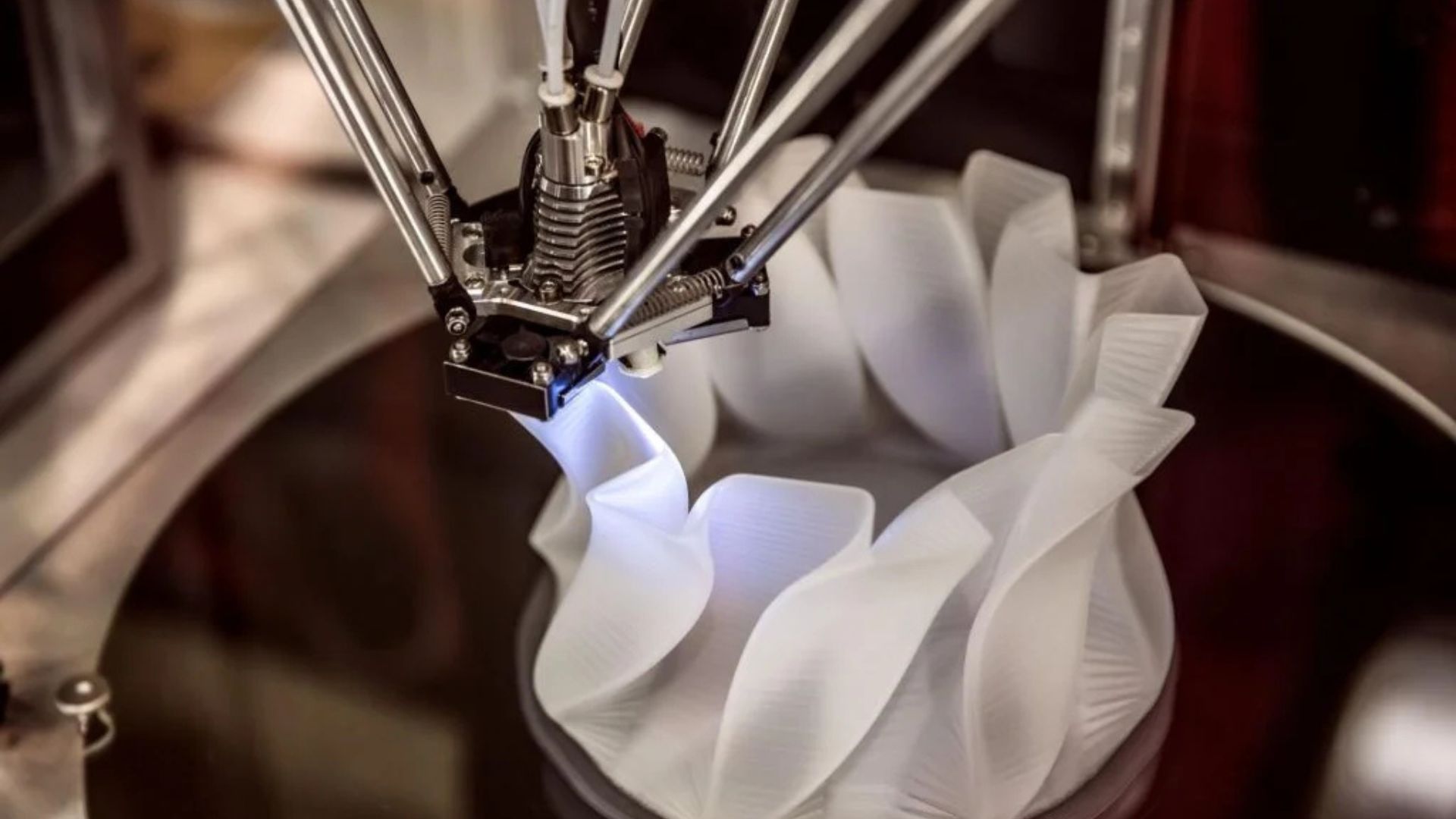

Read original articleA Japanese research team has developed a novel laser-assisted additive manufacturing method to produce industrial-grade tungsten carbide–cobalt (WC–Co) cemented carbides, materials essential for cutting tools and heavy-duty equipment due to their extreme hardness and wear resistance. Traditional powder metallurgy techniques for shaping WC–Co are costly and wasteful, requiring high pressure, elevated temperatures, and sintering, which limit design flexibility and result in significant material loss. The new approach employs hot-wire laser irradiation, combining a laser beam with a preheated filler wire to deposit material precisely where needed, reducing waste and production costs while preserving the material’s hardness and microstructure by avoiding full melting.

The researchers tested two deposition strategies—advancing the carbide rod ahead of the laser and allowing the laser to lead while irradiating the gap between the rod and an iron base. Both methods softened rather than melted the material to enable bonding, minimizing thermal damage. The resulting cemented carbide achieved hardness exceeding 1400 HV, comparable to the hardest

Tags

materialsadditive-manufacturingtungsten-carbidelaser-assisted-3D-printingcemented-carbidesindustrial-manufacturingwear-resistant-materials