Multimaterial 3D printer builds working motor from scratch in hours

Source: interestingengineering

Author: @IntEngineering

Published: 2/21/2026

To read the full content, please visit the original article.

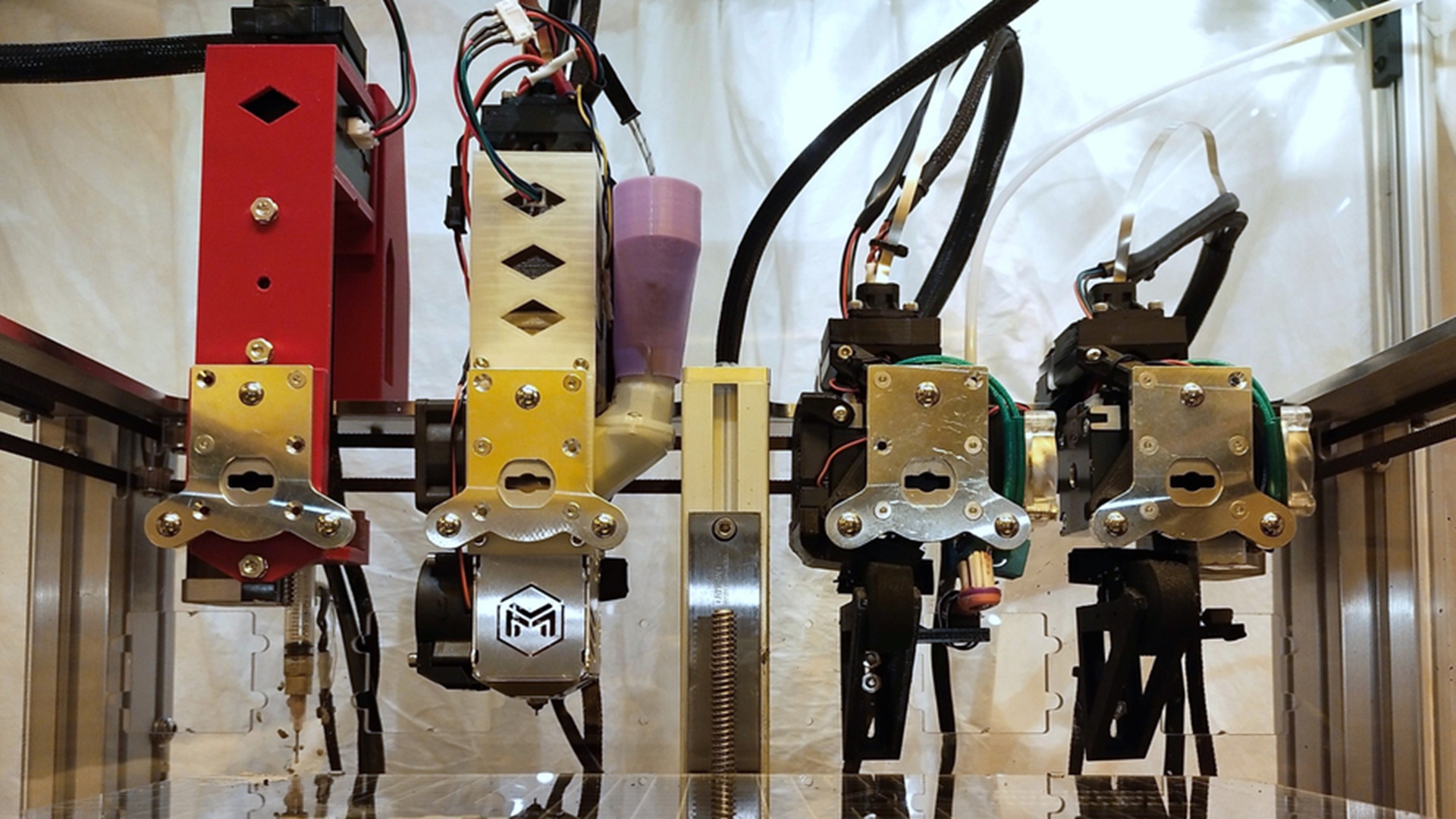

Read original articleMIT researchers have developed a multimaterial 3D-printing platform capable of fabricating fully functional electric motors from scratch within hours. By modifying an extrusion-based 3D printer with four separate extruders to handle different materials—including conductive, magnetic, and structural components—the team successfully printed a working linear electric motor in about three hours. This motor, produced using five materials and requiring only a single post-processing step (magnetization), demonstrated performance superior to conventional linear engines that rely on complex hydraulic systems, with an estimated material cost of just 50 cents.

The innovation addresses the limitations of traditional electric machine manufacturing, which typically involves centralized facilities, multiple fabrication steps, and specialized equipment, often causing delays and increased costs when replacement parts are needed. The MIT platform’s precision sensors and control framework ensure accurate layer alignment critical for electric machine performance. The researchers envision this technology enabling distributed, on-site manufacturing of complex electronic and electromechanical devices, reducing dependence on global supply chains. Future work aims to integrate magnet

Tags

3D-printingelectric-motormultimaterial-extrusionroboticsmanufacturing-technologyconductive-materialsdistributed-manufacturing