Neutron beams help protect US nuclear submarines from weld cracking

Source: interestingengineering

Author: @IntEngineering

Published: 1/9/2026

To read the full content, please visit the original article.

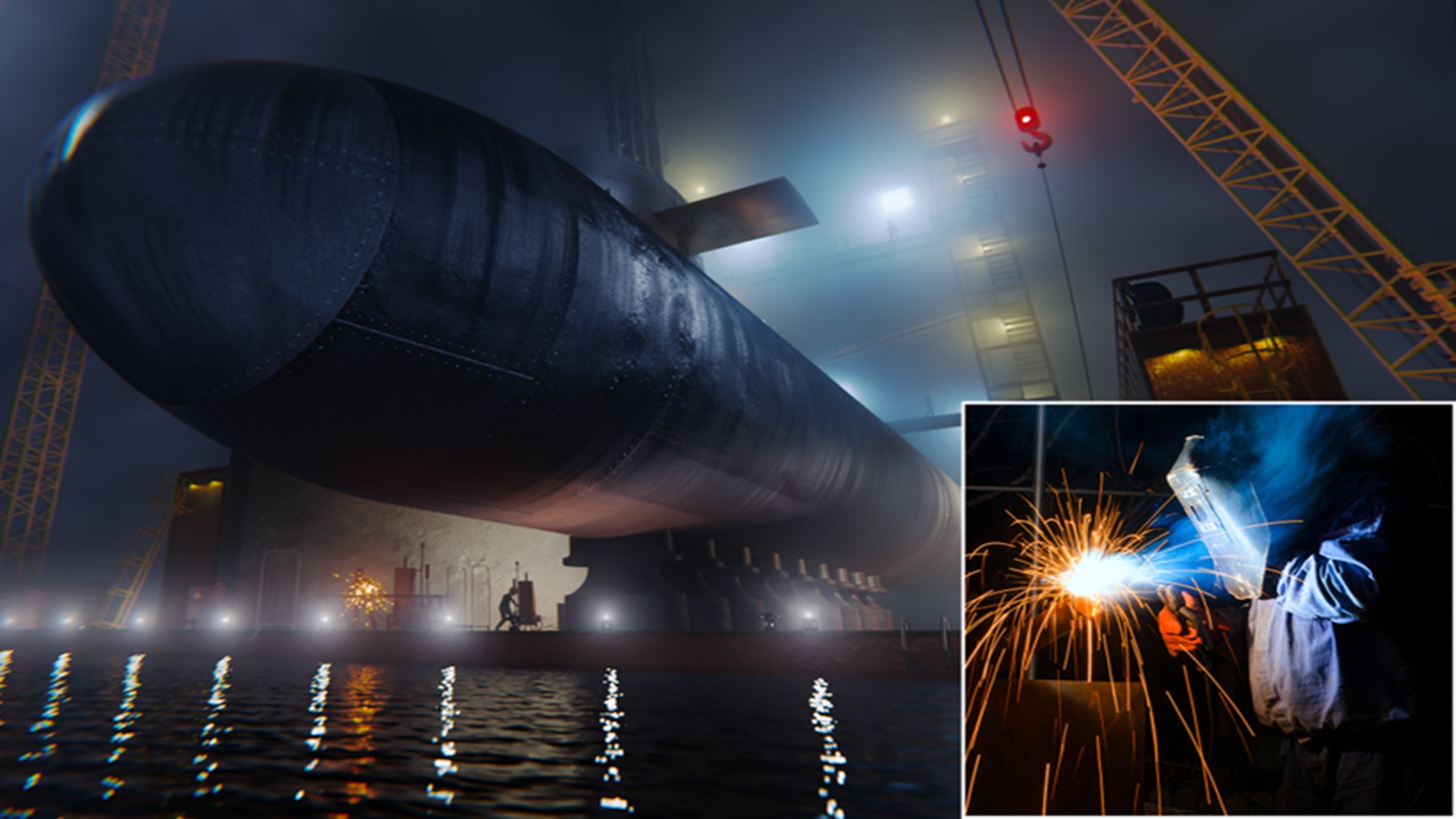

Read original articleScientists are using neutron beam techniques to address weld cracking issues in the US Navy’s nuclear submarines, which operate under extreme pressure and temperature conditions deep underwater. These submarines rely on massive steel plates joined by welding, but ductility dip cracking (DDC)—tiny fissures forming as welded metals cool—remains a significant challenge that can compromise structural integrity over time. The research collaboration between the US Navy, Electric Boat, the University of Connecticut, and Oak Ridge National Laboratory (ORNL) employed neutron scattering at ORNL’s High Flux Isotope Reactor to nondestructively measure internal stresses and detect hidden defects within welded joints, focusing particularly on a copper-nickel alloy commonly used in naval applications.

Neutron diffraction allowed the team to observe changes in atomic lattice spacing caused by residual stresses from welding, while neutron radiography revealed internal density variations. Unlike X-rays, neutrons penetrate thick metals without damage, enabling faster and deeper analysis. This approach, combined with complementary X-ray testing at Brookhaven

Tags

materialsweldingneutron-beamsnuclear-submarinesresidual-stressalloysstructural-integrity