New 3D-printed smart material lets ceramics bend to survive heavy loads

Source: interestingengineering

Author: @IntEngineering

Published: 12/24/2025

To read the full content, please visit the original article.

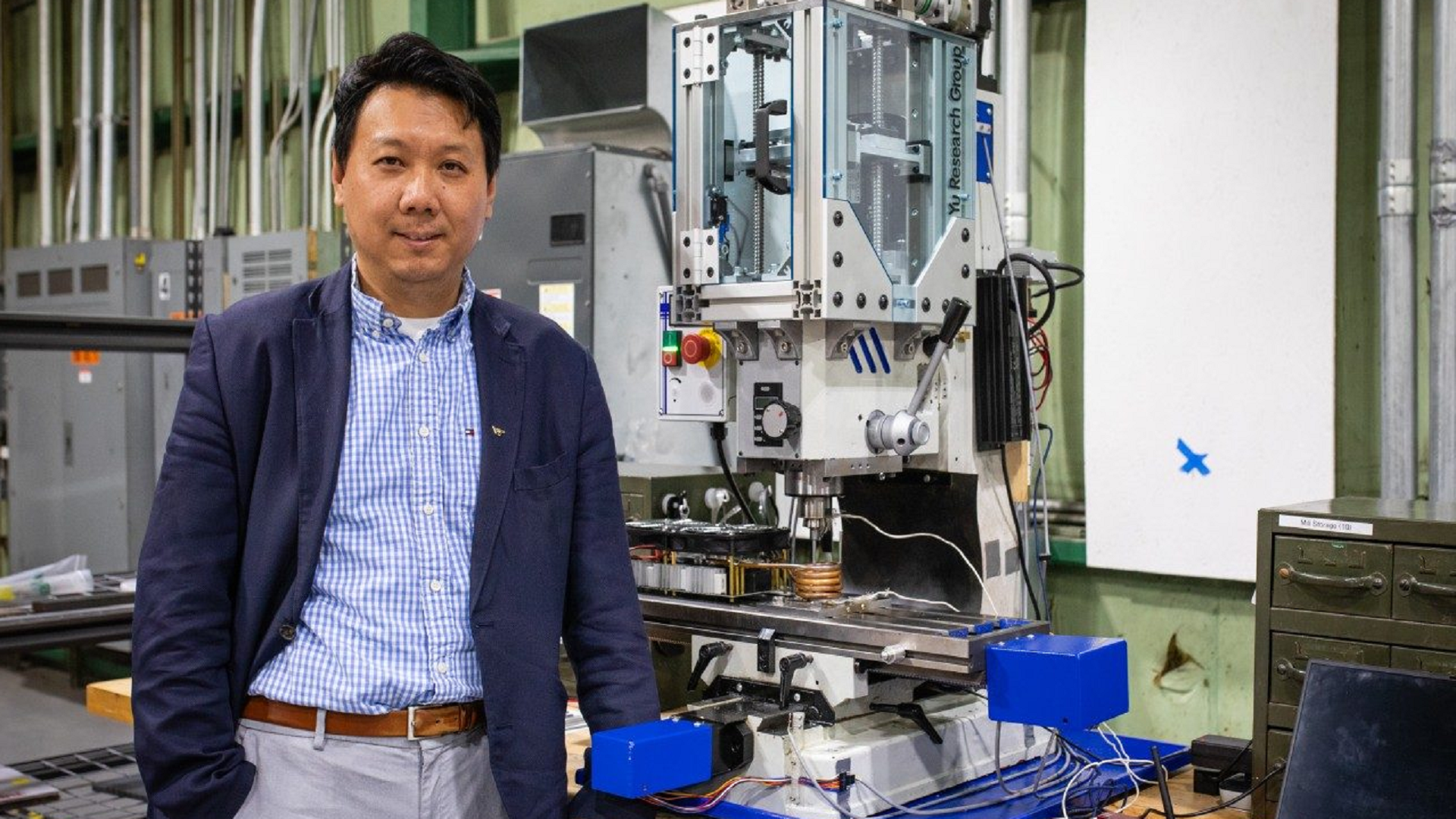

Read original articleResearchers at Virginia Tech have developed a novel 3D-printed smart composite that enables traditionally brittle ceramics to bend, absorb energy, and endure heavy mechanical loads without cracking. Led by Associate Professor Hang Yu, the team embedded tiny shape-memory ceramic particles into metal using a solid-state additive friction stir deposition (AFSC) process, which fuses materials below their melting point under intense pressure. This approach produces a strong, defect-free composite that can undergo stress-induced phase transformations to dissipate energy, allowing the material to withstand tension, bending, and compression while maintaining full density in bulk form.

This breakthrough overcomes a longstanding challenge in materials science, as shape-memory ceramics previously only functioned at microscopic scales due to their tendency to fracture when produced in bulk. The new composite’s multifunctionality and scalability open up promising applications across defense, aerospace, infrastructure, and high-performance sporting equipment, such as vibration damping in golf club shafts. Supported by the National Science Foundation and the US Army Research Laboratory, the research highlights

Tags

materials-science3D-printingsmart-materialsceramicscomposite-materialsadditive-manufacturingshape-memory-materials