Old electroplating trick could shrink nuclear clocks to wearables

Source: interestingengineering

Author: @IntEngineering

Published: 12/11/2025

To read the full content, please visit the original article.

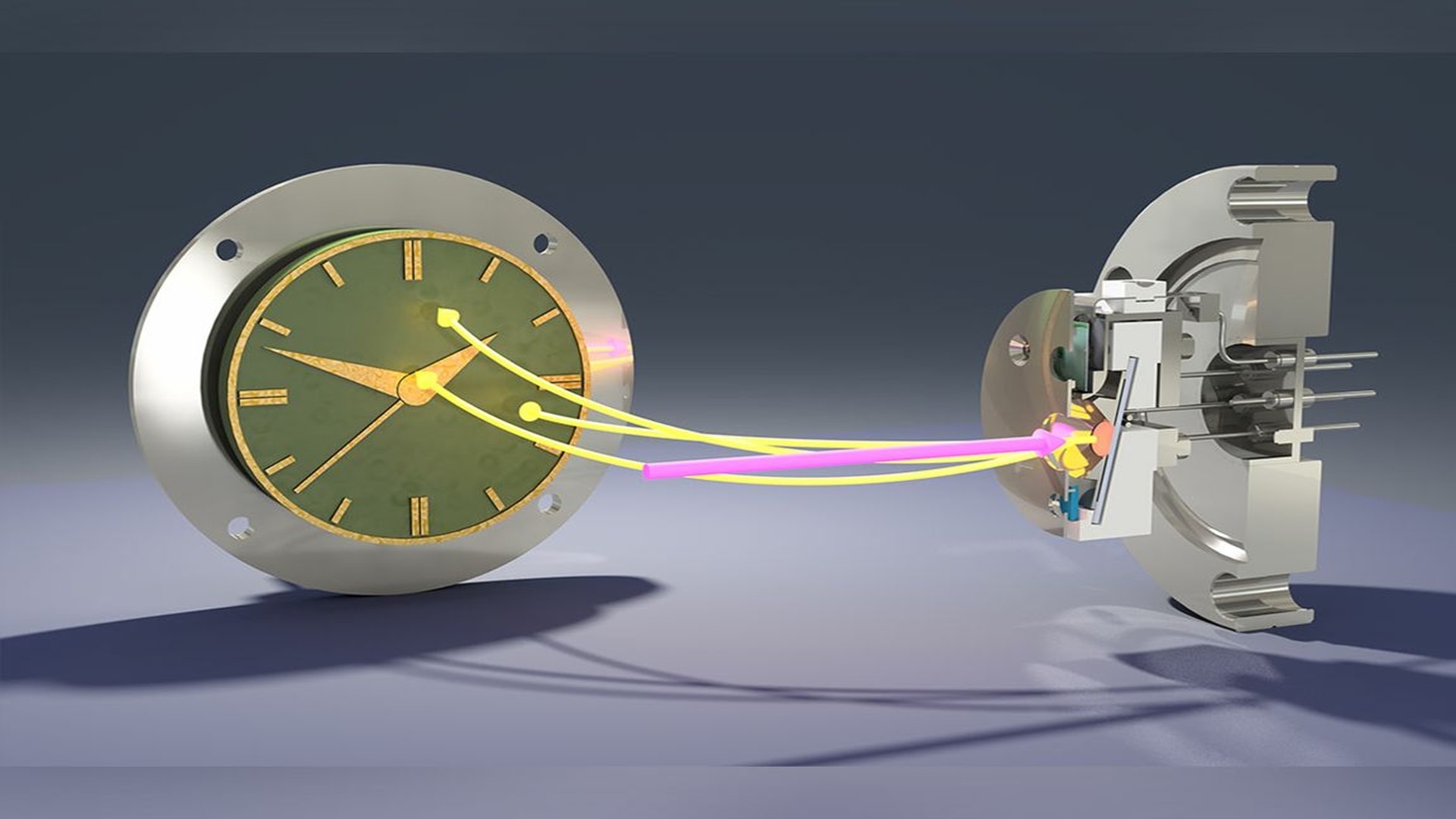

Read original articleA UCLA-led research team has developed a significantly simpler and more efficient method to create thorium-based nuclear clocks, potentially enabling their miniaturization into wearable devices. This new approach replaces the previously complex and time-consuming process of growing specialized fluoride crystals with an industrial electroplating technique, an old method adapted to deposit microscopic layers of thorium onto stainless steel. Crucially, this method uses about 1,000 times less thorium-229—the rare isotope essential for nuclear clocks—while eliminating the need for transparent crystals, as only surface nuclei need excitation and emit detectable electrons rather than photons.

This breakthrough challenges the longstanding belief that the host material for thorium must be transparent for laser excitation. Instead, the team demonstrated that opaque materials can be used effectively by detecting emitted electrons through electrical current, simplifying the construction and improving the durability of nuclear clocks. Thorium nuclear clocks promise exceptional stability and precision, with transformative applications in navigation, communications, and power grids. They could provide resilient timekeeping independent of satellite

Tags

materialsnuclear-clockselectroplatingthorium-229precision-timingnavigation-technologyindustrial-process