UK-made super materials to shield fusion reactors from extreme heat

Source: interestingengineering

Author: @IntEngineering

Published: 1/18/2026

To read the full content, please visit the original article.

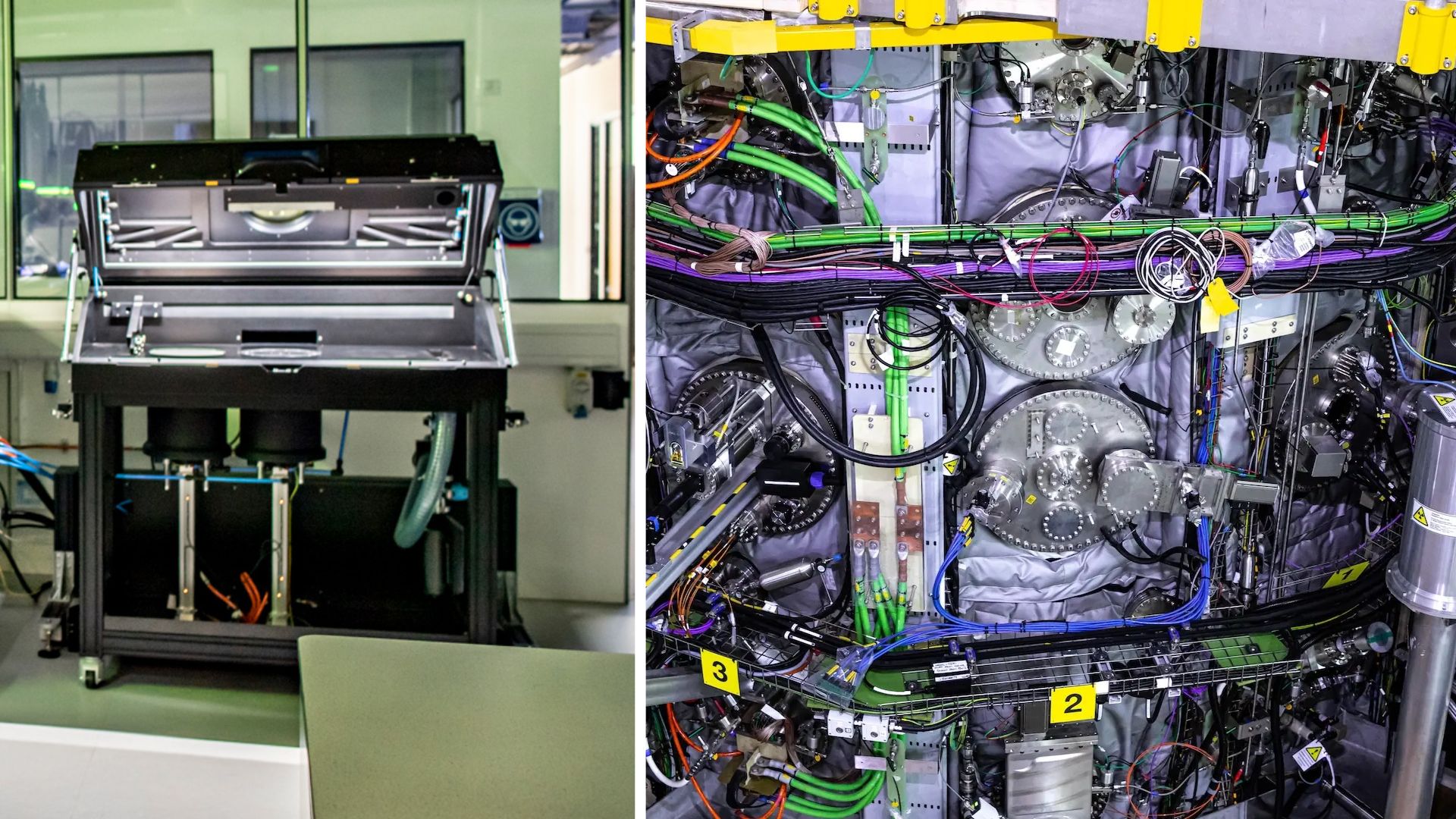

Read original articleThe UK has made a significant advancement toward its goal of operating a prototype fusion power plant by 2040 through the launch of DIADEM, a research initiative focused on overcoming a major materials engineering challenge. Fusion reactors require components that can withstand extreme heat—up to 3,000°C—and intense magnetic fields. Tungsten and copper are ideal materials for these conditions due to tungsten’s high melting point and copper’s excellent heat conduction. However, their vastly different melting points and thermal expansion rates have made traditional joining methods like welding or casting ineffective, often resulting in cracks or separation.

DIADEM, led by the University of Nottingham’s Centre for Additive Manufacturing, is addressing this by using Multi-Metal Laser Powder Bed Fusion (MM-LPBF), an advanced 3D printing technique that simultaneously fabricates tungsten-copper components from the ground up. This process creates “metamaterials” with a smooth microscopic transition between the two metals, eliminating weak seams and improving durability. This breakthrough not only advances

Tags

materialsfusion-energyadditive-manufacturingmetamaterialstungstencopper3D-printing