Why modular movement systems are the future of industrial operations

Source: interestingengineering

Author: @IntEngineering

Published: 12/16/2025

To read the full content, please visit the original article.

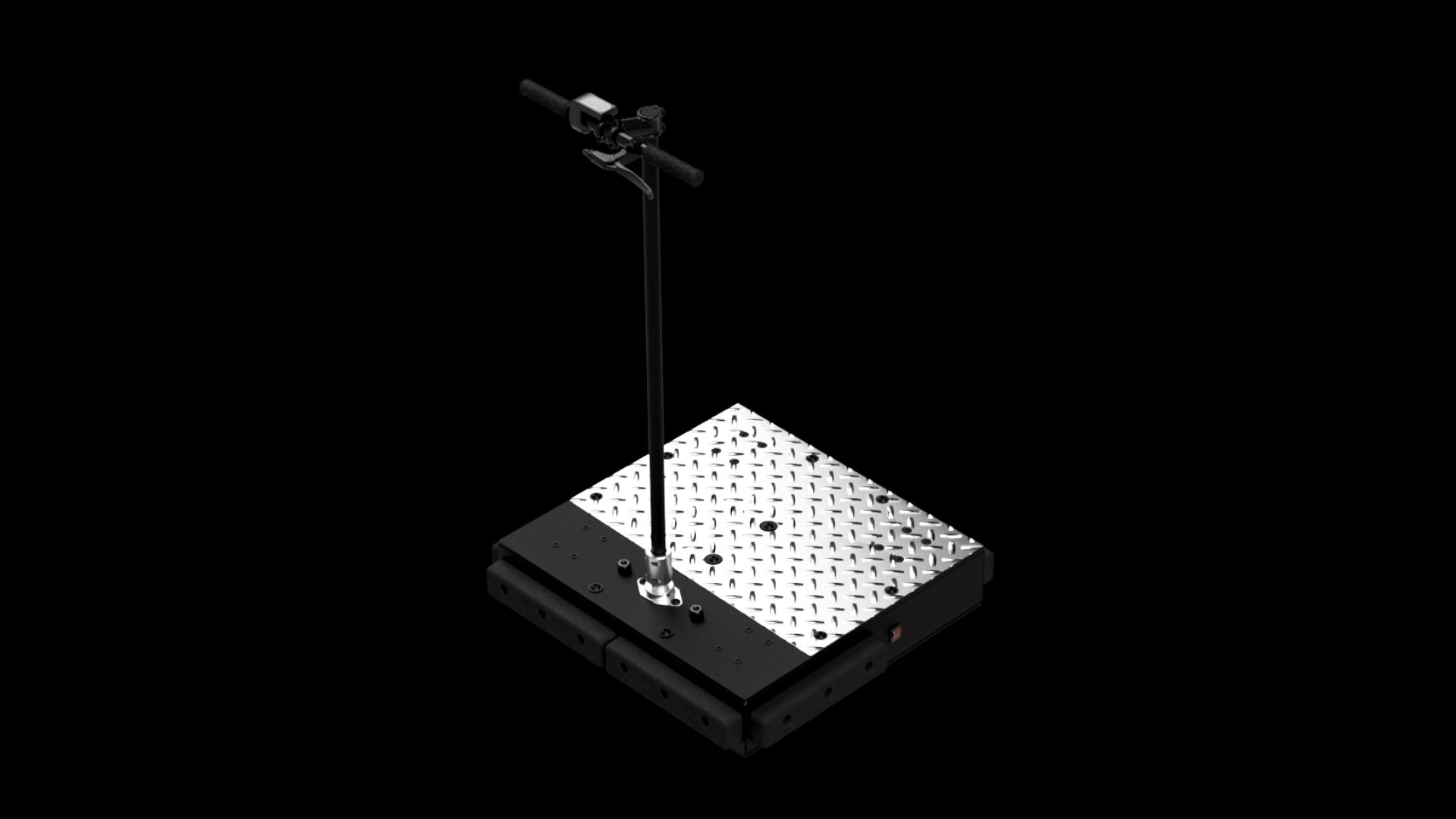

Read original articleThe article discusses the growing importance of modular movement systems in industrial operations, emphasizing their flexibility and adaptability in an environment where product lines and workflows change rapidly. Traditional fixed conveyors and rigid carts, designed for predictable workflows, are becoming obsolete as they cannot easily accommodate evolving operational needs. Modular systems, exemplified by TexTrack’s warehouse scooter, offer lightweight, reconfigurable platforms that separate the movement base from payload modules, allowing quick adjustments to different tasks such as picking, assembly, or replenishment without replacing the entire unit. This adaptability supports faster response to workflow changes and reduces downtime.

A key advantage of modular systems lies in their focus on lifetime value rather than upfront cost. Using advanced composite manufacturing, TexTrack’s scooters are lighter, structurally strong, and feature components that can be individually replaced, significantly lowering repair time and costs over the equipment’s lifespan. This “replace, not rebuild” approach extends asset life and reduces operational interruptions. Additionally, modular platforms are well-suited for integration with emerging warehouse robotics

Tags

robotmodular-systemsindustrial-automationmaterial-handlingcomposite-materialswarehouse-technologyflexible-manufacturing